INDIETRO

INDIETRO

|

|

|

|

|

Coral and Precious Metal Carving

|

|

|

|

|

|

|

|

|

Metal Carving Techniques

Goldsmith metal carving starts with preparing the proper alloy.

Alloys in Italy are subject to special title regulations. The title of an alloy is nothing other than the quantity of precious metal which is present in it.

The minimum title for silver alloys that is allowed by the Italian Government is 800/1000. Other titles allowed are 835/1000 and 925/1000. As far as gold is concerned, the title allowed is 18k, which is equivalent to 750/1000. .

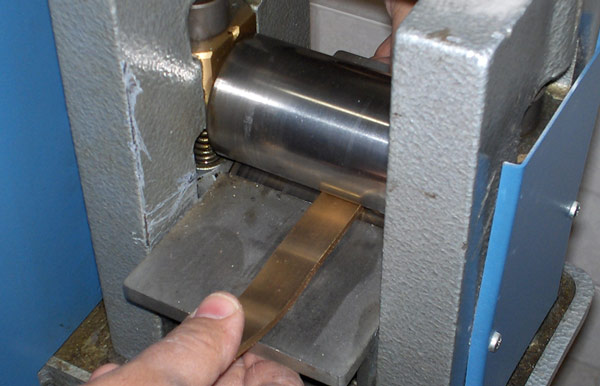

Once we have prepared the alloy, we mould it into bars, which are then rolled into a carving size.

Among the various methods of coral processing, two of them deserve special attention:

Desk Carving

Desk carving is a mechanical operation carried out directly upon the metal in order to make a jewel. The tools used in metal carving are:

-

Melding Nozzles

(per fondere o per effettuare saldature )

-

Rolling Machines (for cutting metal into sheets or wires)

-

Wire-Drawing

Machines (for drawing tiny round-section wires)

- files (of different kinds for remodelling and reshaping purposes)

-

Carving

Saws (for intaglios)

-

Burins

(for setting stones or etching figures or inserting decorations into the metal)

-

And so many other large and small tools

Lost Wax Casting

This process starts from melding the wax in order to obtain the desired mould. Through further treatments, the wax figure "becomes" its analogous metal figure. The processing of the metal figure continues

on the desk up

to its final stage.

Lost wax casting consists of the following stages:

-

Melding

the Object: there are different melding methods according to the wax used, as there are several kinds of waxes, from the soft ones to those which are so hard as to be processed with goldsmith files only.

-

Studying and Applying Wax Canals: wax canals are added to the mould to let the wax out and allow the metal in. This stage is crucial to the success of the melding and the difficulty of polishing the object.

-

Building

the Wax Tree: a wax tree is made, whose branches are the moulds to be melded. At the foot of the tree a mass of wax called materozza is created. When the melded metal is cast into the moulds, the materozza will raise its pressure, thus making it match with the shape of the mould.

-

Building

the Shell: the shell is the refractory plaster cast around the tree; the plaster is cast into a metal cylinder-shaped vessel.

-

Casting

the Wax: the plaster is placed along with the whole metal cylinder-shaped structure into an oven in order to let the wax out and leave the empty mould of the object inside.

-

Melting

and Injection: the melted metal is injected by centrifugal force or the suction obtained as a result of the vacuum created (Vacuum System)

-

Releasing

the Tree: the tree, which is now metal, is released from the plaster as it is dunked, still hot, into water.

.

Coral Carving Techniques

Coral is used both as precious stone in jewellery and in the creation of artistic and ornamental objects. There are basically two productive sectors: plain coral and carving coral.

PLAIN CORAL

Plain coral is used in serial production, which used to be subdivided into in the round sculpture coral and factory coral.

Plain coral processing consists in

creating geometrically-shaped jewellery. The geometric shape is obtained by sawing, scraping or filing material off the object concerned.

The polishing of the object is carried out by barrel-shaking or with wax.

|

|

MANUFACTURING STAGES

-

Choosing: the raw coral collected from the sea is washed and selected according to size, shape and colour in order to choose its most convenient destination. There is a special terminology for raw coral according to its size: terraglio (tiny chunks and branches), terraglione (larger branches), barbaresco (branches whose diametre reaches 4-5mm), corpo (branches whose diametre exceeds 55mm), mostra (much larger pieces), paccottiglia (basically straight branchless pieces).

-

Severing: This operation used to be carried out on a special wooden desk; the piece was carved first by means of a steel triangle-shaped file, then more in-depthly by a saw-toothed sword, and finally severed with large thongs. Nowadays, tiny diamond-lined disks are used instead.

-

Sifting: the coral which has just been severed, divided into groups and selected according to its colour, goes through a series of brass-buttoned sieves with holes which are gradually larger, so as to obtain various stocks of different sizes.

-

Boring: coral used to be bored by means of a small bow-shaped steel-tipped drill. It was fully perforated in order to let necklace threads through, or half-perforated for pivot hosting in the case of buttons, balls and pendula. Nowadays, instead of the above-mentioned tools, electric engines are used for the purpose.

-

Planing: during this stage, coral was threaded on a tight iron wire in order to be slendered down by a grinding stone.

-

Rounding: factory coral used to be modelled with a large manual grindstone. In-the-round sculpture coral was further modeled and refined with a tipped tempered steel file called quadrella for perfect rounding. Nowadays electric tools are used for the purpose.

-

Colour Cleansing: coral used to be bathed in hydrogen peroxide in order to restore it to its genuinely shining colour.

-

Polishing: coral pieces used to be placed in fabric sacks or excentrically-shaken barrels together with soapy water, pumice and calcinated deer horn powder. The abrasive propriety of the above-mentioned substances "did the polishing". Nowadays, electric-engine-shaken barrels are used for the purpose.

-

Selecting: coral pieces are further selected according to size, colour and quality.

-

Threading: the coral pieces thus selected are threaded into sequences of various lengths.

ANCIENT MANUFACTURING PRODUCTS

-

Frange: threads of tiny pieces of coral about 5-50mm long, horizontally bored at one end; pieces go shorter from the centre of the thread to its ends.

-

Spezzati: threads of small pieces of coral, about 4-10mm long, horizontally bored at the centre.

-

Rocchielli: small pieces of coral slightly thicker than spezzati, straight with slightly wedged edges.

-

Cupolini: fully wedge-tipped occhielli.

-

Mezzi

finiti: small chunks of coral similar to cupolini, but wrought at the centre in order to reduce their thickness. This operation used to give more matching adherence to the chunks, and thicker sequences were obtained as a result.

-

Finiti: further processing of mezzi finiti, so as to obtain two joint balls. The juncture was bored for a thread to be placed through.

-

Cannettine: straight chunks of variable size and thickness, smoothed down to a cylindrical shape and bored through their length.

-

Mezzania: very short smooth-edged cannettine (6mm long at the most).

-

Chiattelle: coral washers of various thickness, with rounded edges.

-

flotticelle: coral cylinders slightly smoothed at the ends, which used to be grouped in 45-240cm-long threads.

-

Olivette: more or less elongated olive-shaped pieces of coral.

-

Corpetti: small coral balls, slightly shorter than botticelle;

-

Corpi: slightly larger corpetti whose diametre is 4-5mm.

-

Filotti: nowadays called factory coral, they are similar to corpi in shape, though their size is larger.

-

Tondo: perfectly round balls of coral

-

Maometti: long chunks of coral, about 3-5cm long, bored through their length. Not all of the above mentioned types are still produced today

-

Colletti: threads of 18cm long spezzati.

-

Sciarpe: approximately 120cm-long spezzati and rocchielli.

-

Filo

di grossezza: thread which used to group the largest corals of a given stock.

-

Mazzi

di grossezza: bunches consisting of one filo di grossezza and 24 threads of equal shape and size.

-

Codini: small threads which used to group a few very large grains of coral.

-

Caporesti: bunches of 6-12-mm-thick threads, each weighing 250gr.

-

Fili

accodati: threads of coral pieces from the same cut, going shorter from centre to ends.

- Fili

uguali: threads of coral pieces of the same cut and size.

CARVING

Coral carving enables us to obtain products of various shapes. No matter how tortuous, complex and unpredictable these shapes can be, we can make real sculptures sometimes. As is the case with plain coral, coral carving entails sawing, filing, cutting, burining and lathing off material from the object concerned. Lathes are made of various materials and sizes and are driven by electric engines. The mostly used are equipped with steel bars and and their heads are made of tungsten carbide, emery or diamond.

|

Burins are sharply-bladed broad-handled chisels.

They are used with a small cloth helping the carter drive the blade correctly into the material being carved.

|

This image was taken, with the author's prior assent, from www.ludovicodelia.it

This image was taken, with the author's prior assent, from www.ludovicodelia.it

Micro-electric-engine-driven lathes ensure easier and quicker lathing of material than it could be done with burins, although the resulting surface of the object does not come as smooth.

This image was taken,

with the author's prior assent, from www.ludovicodelia.it

This image was taken,

with the author's prior assent, from www.ludovicodelia.it

Created by LUDOVICO D'ELIA Medusa (Jellyfish) :: coral :: 3.7x3.4x0.7cm

This image was taken, with the author's prior assent, from www.ludovicodelia.it

This image was taken, with the author's prior assent, from www.ludovicodelia.it

Created by LUDOVICO D'ELIA

La paura dei mediocri (the dull's fear) 1998 :: coral, gold, marble :: 12x7x7cm

cm |

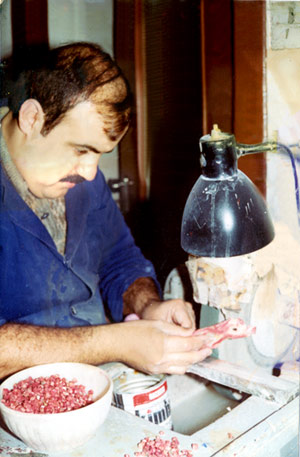

Vincenzo Del pezzo

Vincenzo Del pezzo preparing a branch of raw coral for sculpting

This image was taken,

with the author's prior assent, from www.ludovicodelia.it

This image was taken,

with the author's prior assent, from www.ludovicodelia.it

Created by LUDOVICO D'ELIA Cavalluccio Marino (Seahorse) 1999 - 2002 :: coral, gold, pearl :: 8cm

This image was taken, with the author's prior assent, from www.ludovicodelia.it

This image was taken, with the author's prior assent, from www.ludovicodelia.it

Created by LUDOVICO D'ELIA

la vanità 1999 :: coral :: 14x4x4 cm

|

|

|

|

|

|

|